Background

The Spanish customer needs a 3-meter-wide non-woven fabric laminating machine for waterproof applications, thus having high requirements for product quality. It is required to be suitable for laminating various materials such as EVA, PP, HDPE, and LDPE on non-woven fabrics, and also needs to test the thickness uniformity of the 3-meter width.

Solution

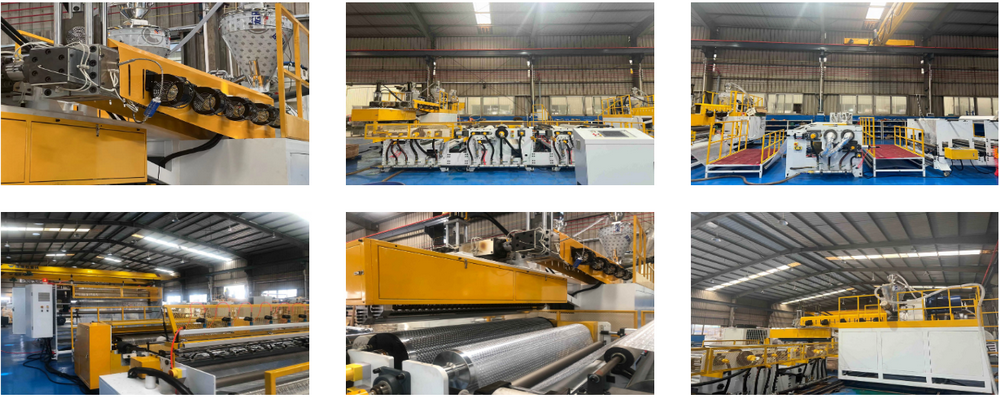

They adopted our non-woven fabric laminating machine featuring a large unwinder (max. Ф1200mm), high capacity (600-900 kg/h production), wide format (3000 mm max working width), multi-material compatibility (PP/LDPE/HDPE), precision coating via T-die for uniform lamination, smart OC-X-ray thickness monitoring, and a climate-controlled air-cooled electrical cabinet.

Benefits

The machine meets the high-quality requirements for waterproof non-woven fabric lamination with multiple materials, ensures the thickness uniformity of the 3-meter width through precise coating and smart monitoring, and has high production capacity, fully satisfying the customer's needs.

Background

Czech customer needs a high-output bubble film machine, with a thickness of 500 kg per hour, a production capacity of at least 600 kg per hour, and a speed of 70-80 meters per minute.

Solution

We enlarged the screw and added fans to cool each temperature zone of the screw to achieve high output. Besides, the diameter of the bubble roller was increased to enhance the cooling effect.

Benefits

Meets the customer's requirements for high output, speed and thickness, ensures stable production, and improves production efficiency.

Background

The Brazilian customer demands blue bubble film pool film with a width of 4.2 meters, a dimension that represents an unprecedented super-wide specification in the bubble film manufacturing industry, posing significant technical challenges in terms of material uniformity and structural stability.

Solution

To address the critical issue of width-induced material inconsistency, we employed a precision-machined die head with micron-level tolerance control, ensuring homogeneous melt distribution across the entire 4.2-meter span. Concurrently, a reverse winding mechanism was integrated into the production line, enabling external bubble orientation during the winding process to facilitate direct market distribution without additional processing.

Benefits

The implementation of advanced die head technology successfully achieved 4.2-meter super-wide blue bubble film pool cloth with exceptional dimensional stability and material uniformity. The reverse winding configuration optimizes post-production logistics, allowing for immediate commercialization, thus fully satisfying the customer's specialized requirements in both product performance and operational efficiency.

Background

Due to the high labor costs in South America, the Argentine customer requires an automated system for precise calculation of bubble film thickness. They need the machine to automatically and accurately produce bubble film with the set thickness, such as 28 grams per square meter, while expecting to reduce production and labor costs through efficient material management.

Solution

We integrated an Italian weighing system into the production line to achieve precise automated control of bubble film thickness. This system enables the machine to automatically adjust production parameters based on the set weight per square meter (e.g., 28g/m²), ensuring the output thickness matches the preset value with high accuracy. Additionally, the system is equipped with a four-color mixing function, which supports flexible switching between different production formulas. By automating the material proportioning and thickness control processes, it minimizes manual intervention.

Benefits

The Italian weighing system realizes precise automated control of bubble film thickness, eliminating manual calculation errors and ensuring stable product consistency. The four-color mixing function adapts to diverse production formulas, reducing material waste and lowering labor costs significantly. Overall, it enhances production efficiency while cutting down comprehensive costs, perfectly addressing the customer's needs in the context of high labor expenses in South America.

Background

The Indian customer intends to utilize 100% recycled PP material of inferior quality, characterized by a gray hue, to minimize raw material costs. Additionally, the requirement includes processing the output into bubble film sheets with a fixed length of 2 meters.

Solution

We implemented targeted process optimization to accommodate the 100% recycled PP material, addressing issues such as material impurity and melt instability through modified screw design and enhanced filtration systems, ensuring consistent production of gray bubble film despite the low-grade feedstock. Concurrently, a high-precision servo-driven cutting mechanism was integrated into the production line, enabling accurate slitting of the bubble film into 2-meter sheets with a dimensional tolerance of ±5mm.

Benefits

The optimized process successfully enables the utilization of 100% recycled PP material, achieving a 30% reduction in raw material expenses for the customer. The precision cutting system ensures strict compliance with the 2-meter length specification, while the stable production of gray bubble film sheets meets the customer's cost-saving objectives without compromising on basic product performance, thereby enhancing overall production economy.

Address : No.4 Yangda Road, Xiyong Area, Lunjiao Town, Shunde District, Foshan City, Guangdong Province, China (P.S.code:528308)

Tel : 0757-22817002

Website : WWW.ZTECHMC.COM

copyright : ZTECH

Powered by : sowho.cn